Processes in the clean room

Rinsing of the product in the laboratory washing machine

The actual cleaning process starts with the rinsing of the product in the laboratory washing machine. Products are rinsed with DI-water < 50 μS (deionised, demineralised water). Rinsing with other DI water values is possible upon request.

Packing under LAF

The rinsed product is packed in an SBS (sterile barrier system) under LAF (LAF Flow Box).

Thermal process / labelling

The product is thermally treated in the steriliser.

Finally the product is labelled. Each label carries the following information:

- Product number

- Product name

- Pack size

- Lot number

- Production date

- Expiration date

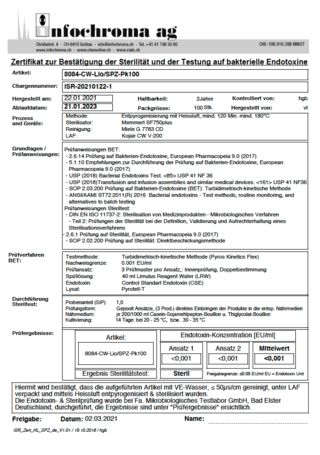

Quality control / lot specific certificate

Each cleaned product is visually inspected for defects before samples of each lot are sent to an independent accredited microbiology laboratory. This laboratory analyses the samples for sterility and undertakes the BET (bacterial endotoxin test).

Only after the laboratory has confirmed that the test results comply with the requirements, the cleaned products held in the quarantine area are released for sales together with a lot specific certificate.