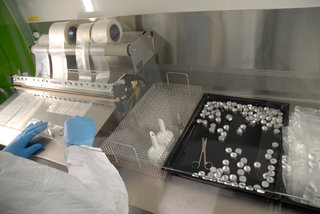

Sterile and depyrogenated vials & closures from the clean room

Available processes

- Purified water rinse (de-ionised / de-mineralised water)

- Packing in low-particle environment

- Steam sterilisation

- Hot air sterilisation

- Hot air depyrogenation

- E-Beam sterilisation in co-operation with contract partners

- Individual pack sizes

- Individual combination of products per unit

- Production of small, medium or large quantities

Quality control

- Validated process

- Skilled staff

- IQ/OQ - equipment qualification, rotative PQ

- Visual inspection for visual defects of 100 % of the finished products

- Analysis for sterility and BET test (bacterial endotoxin-test) carried out by an independent microbiology laboratory

- Detection limit BET: <0.001 EU/ml

- Particle counting according to USP 788